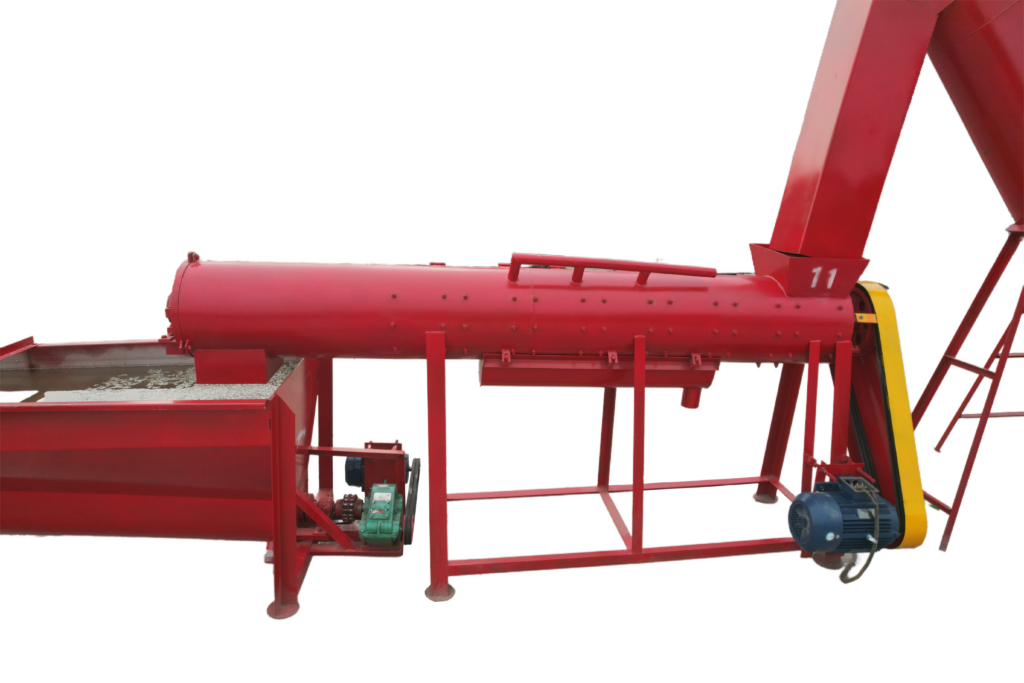

Plastic Flakes Friction Washer

plastic Flakes Friction Washer Machine For plastic recycle

| Capacity | 500-100kg/h |

| Length | 3000mm |

| Power | 7.5kw |

| Out Layer | 4mm |

| Blade Thickness | 6mm |

What Is Friction Washing machine?

Friction washing machine is used in the plastic recycling process, which is an important step to improve the purity of the end product plastic and enhance the economic value of the end product.

The high-speed friction washing machine can remove dirt, grease, and other dirt and pollutants from plastic flakes and films, making the plastic flake raw materials entering the next processing process cleaner. Transform dirty plastic waste into clean recycled plastic pellets.

In the recycling business, washing is an imperative step to increase the value of the desired materials. Sink-float tanks and friction washing machines are the common means to achieve this goal.

What Is Working Principle Of friction Washing Machine?

The main components are the large rotor with several arrays of paddles, dewatering screen and cleaning manifold for water injection. The Friction Washer is accumulated on an inclined frame.

The blades on the main shaft push the material forward,the fast-rotating shaft and paddles transport up and hit the materials against the screen, just like how a laundry machine works. Dirt and grease are then driven out of the system, and sprayed away by water nozzles. The dirty water and contaminant then discharge at the bottom of the machine. The cleaned materials leave at the top.

Importance Of Friction Washing Machines

Efficient Machine friction washing machines are commonly used in various applications in industrial processes and recycling businesses. Friction washing machines convert dirty waste plastic waste raw materials into clean plastic raw materials, producing recycled plastic pellets that have a higher economic value than plastic pellets containing a lot of impurities in markets that value product quality.

Features Of Friction Washer?

The friction washer is heavy duty and available in various models, featuring:

No blockage of materials

Cold wash

Highly efficient to clean

Easy maintenance

Rigorously wash plastic materials

Compact design comparing water tank

Applications of Friction Washer

Clean highly contaminated materials or big plastic flakes or plastic films which come from a primary shredder or from a crusher. It excels in cleaning agricultural films, rigid plastics, and PET, PP, PE, HDPE flakes.

If your plastic flakes are not heavily contaminated, the flakes are immediately wet washed to obtain clean regrinds. Following by a vertical dryer and an extraction, the regrinds are easily collected, saving your labour costs.

What are the important core components of Friction Washer?

The main shaft, blades, and unique hexagonal screen help to increase friction strength.