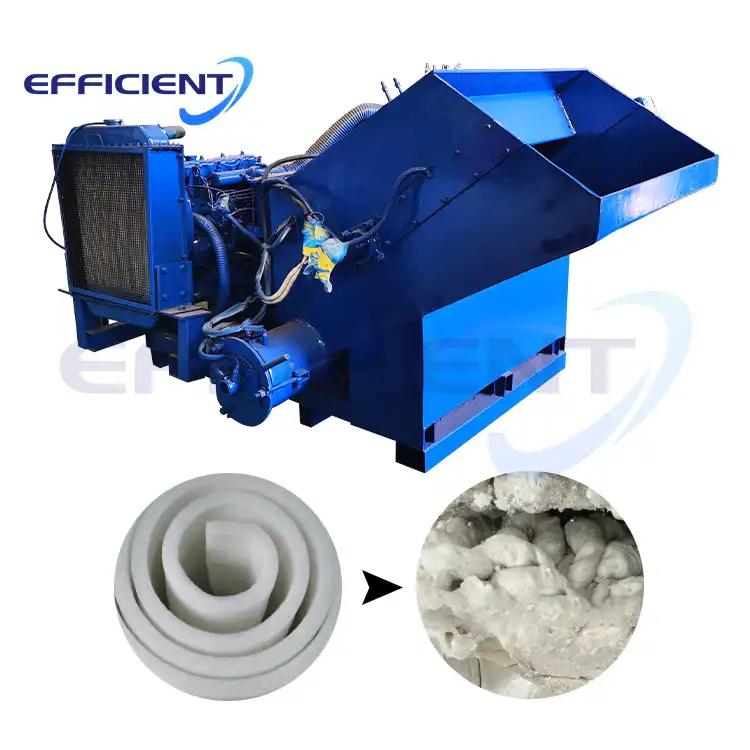

Máquina de fusión en caliente de espuma plástica

Máquina de fusión en caliente de espuma plástica para la venta

Máquina de fusión en caliente de espuma plástica

Marca: EFICIENTE

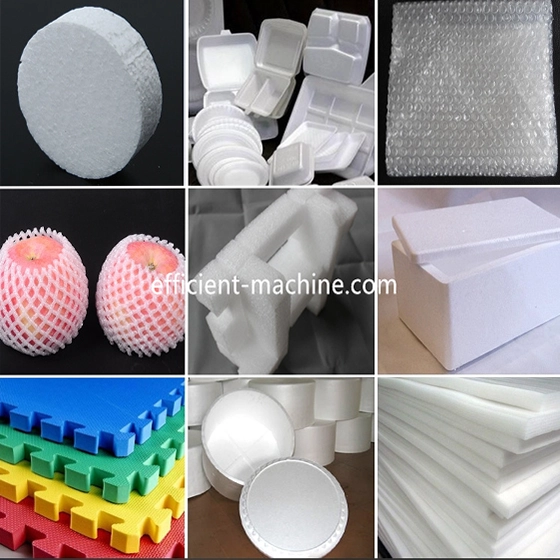

Materiales aplicables: EPE (polietileno expandible), EPS (poliestireno expandido).

Ámbito de aplicación de la máquina de fusión en caliente de espuma

Adecuado para el reciclaje de diversos plásticos espumados.

Espuma plástica

Espuma plástica

Principio de funcionamiento de la máquina peletizadora termofusible de espuma plástica

La máquina peletizadora de espuma plástica termofusible utiliza una cuchilla trituradora de doble eje para romper el material de espuma plástica en pedazos más pequeños e ingresar a la pantalla. El material que no puede entrar en la pantalla se rompe aún más y cae dentro de la pantalla.

Luego, la máquina granuladora de fusión en caliente de espuma plástica ingresa a la máquina principal y el tornillo gira a alta velocidad para transportar el material roto al cilindro cónico. El material se calienta y funde mediante el calentador de mica.

Luego, la máquina peletizadora de fusión en caliente de espuma plástica transporta el material fundido al molde cuadrado de formación. El material comienza a enfriarse y exprime un objeto cuadrado reciclado del molde.

De acuerdo con la longitud requerida, la máquina cortadora corta automáticamente la máquina peletizadora de fusión en caliente de espuma plástica para completar el proceso.

Características de la máquina peletizadora de fusión en caliente de espuma plástica

1. Tiene las ventajas de un gran par, alto rendimiento, ningún ruido y resistencia al desgaste;

2. Alto grado de automatización, ahorro de tiempo y conveniencia;

3. Se puede controlar la temperatura del calentamiento segmentado, lo que mejora la calidad del producto terminado y al mismo tiempo ahorra mucha electricidad;

4. Tiene las ventajas de una gran proporción de trituración, alta eficiencia de producción y tamaño de partícula de descarga ajustable;

5. El dispositivo de accionamiento de la máquina está equipado con protección eléctrica para evitar que fallas accidentales causen daños al equipo;

6. Es conveniente para el tratamiento posterior de residuos de espuma y las partículas procesadas están libres de burbujas, lo que ahorra espacio de almacenamiento.