ماكينة الضغط البارد على الرغوة البلاستيكية

آلة الضغط البارد للرغوة البلاستيكية للبيع

آلة الضغط البارد للرغوة تسمى أيضًا آلة الضغط البارد EPS EPE ، وهي آلة شائعة في آلة إعادة تدوير الرغوة البلاستيكية.

تتمثل الوظيفة الرئيسية لآلة الضغط البارد للرغوة البلاستيكية في تقليل حجم الرغوة البلاستيكية وتقليل المساحة التي تشغلها نفايات الرغوة البلاستيكية أثناء عملية إعادة التدوير، مما يسهل تخزينها ونقلها.

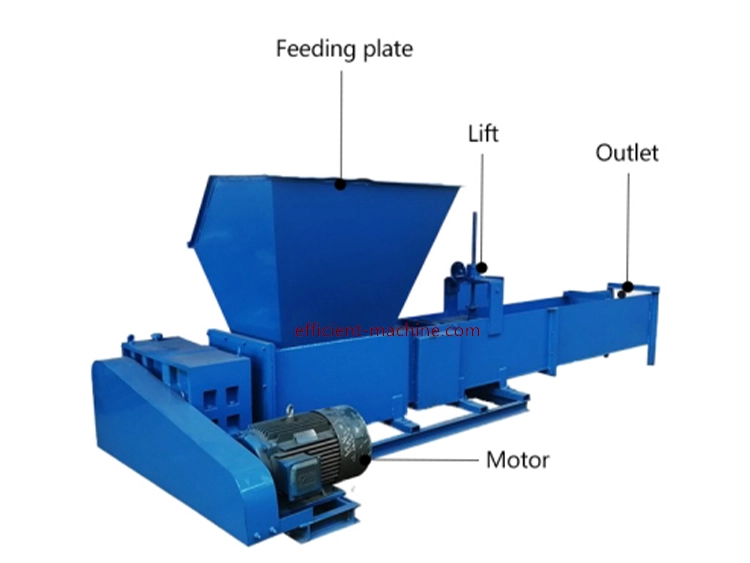

هيكل آلة الضغط البارد للرغوة البلاستيكية

مدخل تغذية كبير الحجم: وفقًا للمواد الخام المختلفة للعميل، ومصمم خصيصًا للعميل.

جهاز تنظيم الضغط: يوجد جهاز تنظيم الضغط أمام قسم الضغط لضبط نسبة الضغط.

ميزات آلة الصحافة الباردة الرغوة البلاستيكية

كتلة رغوة EPS المضغوطة تصل إلى 30 مرة.

كثافة عالية بعد الضغط.

بعد الضغط، من السهل قطع كتلة الرغوة وتخزينها وتكديسها.

آلية ما قبل التكسير مدمجة، كفاءة عمل مستقرة.

تتوفر أحجام مختلفة من أحجام فتح التغذية.

المعدات بسيطة ومريحة، مع قدرة قوية على التكيف ومساحة صغيرة، ومناسبة لضغط EPS في مناسبات مختلفة.

إنه آمن وسهل التشغيل، مع كفاءة عالية، ضوضاء منخفضة وحماية البيئة.

إنه يقلل من مساحة التخزين وتكلفة النقل لـ EPS ويستخدم على نطاق واسع في المصانع وموانئ الصيد والمستودعات ومحلات السوبر ماركت، إلخ.

المواد القابلة للتطبيق

المنتج النهائي

ورشة عمل

إن آلة الضغط على البارد للرغوة البلاستيكية التي تنتجها شركة Efficient Machinery عبارة عن جهاز ميكانيكي يقوم بضغط البلاستيك الرغوي وإجراء معالجة الضغط البارد على أساس مبدأ الدوران الحلزوني لتوليد الضغط.

عند الاستخدام، يحتاج المشغل فقط إلى رمي الرغوة في القادوس، ويتم سحق الرغوة وضغطها حلزونيًا بواسطة آلية التمزيق والسحق الخاصة بالمعدات. بعد معالجتها بالآلية الحلزونية، يتم إنتاج كتل ضغط بلاستيكية رغوية مربعة. يتم تقليل حجم الرغوة بشكل كبير، وزيادة الكثافة، وهو مناسب للتخزين والنقل أثناء عملية إعادة تدوير الرغوة.

كيفية اختيار ماكينة الضغط البارد على الرغوة البلاستيكية

1. يُنصح بالشراء من إحدى الشركات المصنعة العادية لآلات الضغط البارد على الرغوة البلاستيكية. تنتج بعض الشركات المصنعة معدات ذات أداء غير مستقر وأسعار مرتفعة. لذلك، الشراء من مصنع عادي يمكن أن يضمن جودة الآلة بشكل فعال. تعمل شركة Efficient Machinery في إنتاج آلات إعادة تدوير الرغوة البلاستيكية لسنوات عديدة ويمكنها توفير آلة الضغط البارد للرغوة الأكثر فعالية من حيث التكلفة.

2. نموذج آلة الضغط البارد للرغوة البلاستيكية، نظرًا لأن المستهلكين المختلفين لديهم احتياجات مختلفة للمعدات، فإن الشركات المصنعة ستنتج مجموعة متنوعة من نماذج معدات آلة تصنيع بلوك الرغوة. إذا أردنا تحسين كفاءة الإنتاج، فمن المستحسن أن تختار آلة ذات منفذ تغذية أكبر ضمن نفس الطراز، بحيث يتم تحسين كفاءة هذه المعدات في الاستخدام المستقبلي. إذا كنت لا تعرف العديد من النماذج، يمكنك ترك رسالة لتخبرنا باحتياجاتك. سيقدم لك مدير المبيعات النصائح المهنية. يمكننا أيضًا توفير آلة الضغط البارد للرغوة البلاستيكية المخصصة.

حالات التعاون الناجح

احتياطات استخدام ماكينة الضغط البارد على الرغوة البلاستيكية

في عملية استخدام آلة الضغط البارد للرغوة البلاستيكية، من المحتم أن تكون هناك أعطال. عند حدوث الفشل يجب تحقيق النقاط التالية:

1. تُصدر مثبتات مخفض المعدات أصواتًا عالية. الحل هو تشديد واستبدال السحابات التالفة.

2. ترتفع درجة حرارة خزان زيت الضغط البارد للرغوة البلاستيكية. الحل هو إضافة أو طرح الزيت عندما يكون مستوى الزيت في خزان الزيت لآلة الضغط البارد للرغوة البلاستيكية مرتفعًا جدًا أو منخفضًا جدًا. يجب استبدال الزيت الهيدروليكي في الوقت المناسب. تحقق من المحامل. إذا كانت تالفة، فإنها تحتاج إلى استبدالها.

3. ماكينة الضغط على البارد للرغوة البلاستيكية بها تسرب للزيت. قد يكون سبب هذه المشكلة هو سوء الختم. استبدلها بواحدة جديدة أو أعد إغلاقها.

4. لا يمكن لآلة الضغط البارد على الرغوة البلاستيكية أن تعمل بشكل طبيعي. تحقق أولاً مما إذا كان المفتاح به اتصال ضعيف. إذا كان الأمر كذلك، قم بإصلاحه أو استبداله. افحص ملف المحرك لمعرفة ما إذا كان به دائرة قصر. قد يكون سبب انخفاض الجهد هو سلك الطاقة الطويل جدًا أو الرفيع جدًا.