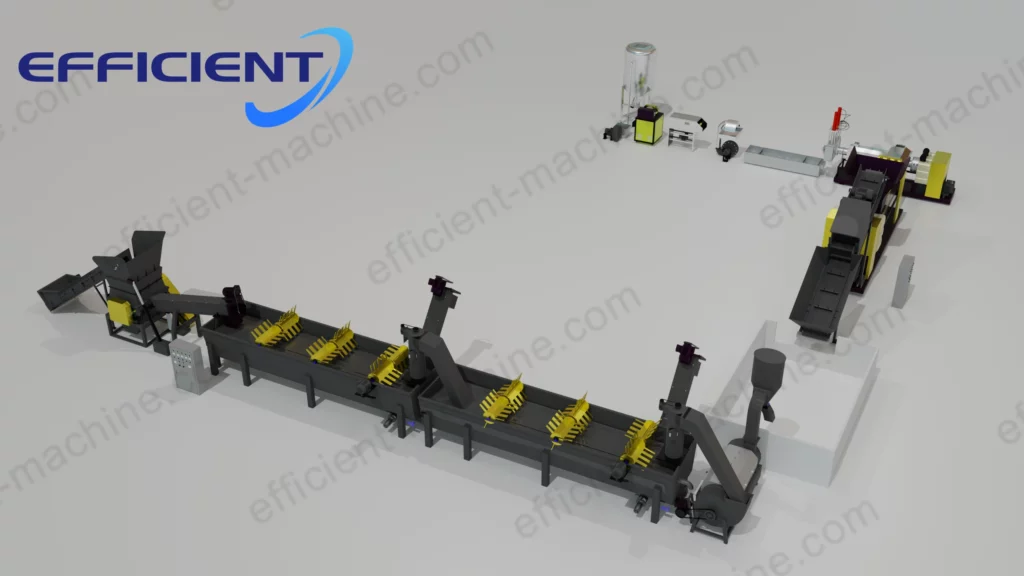

Various Plastic Recycling Machines/Line

PET Hot Washing Granulator Line

Capacity: 500kg/h, 1t/h, 2t/h, 3t/h, 5t/h

PVC content/(mg/kg)≤500

True color content/% ≥90.00

Moisture/% ≥3.0

Impurity content/(mg/kg)≤800

Flake size:16mm-18mm, can be customized.

Advantages: energy saving, modular design, simple operation.

Materials: cold drink bottle such as mineral water bottle, soda water bottle, coke bottle ect.

Plastic Flim Recycling Pelletizing Line

Capacity: 100kg-500kg/h, 1-5t/h.

Particle Length: 4mm(conventional), can be customized.

Particle Diameter: 3mm(conventional), can be customized.

Warranty: 1 year.

Raw Materials: plastic film,such as disposable plastic bags, agricultural films, packaging plastic film ect.

hard Plastic Recycling Pelletizing Line

Capacity: 100kg/h, 200kg/h, 300kg/h, 500-800kg/h.

Particle Length: 4mm(conventional), can be customized.

Particle Diameter: 3mm(conventional), can be customized.

Warranty: 1 year.

Raw Materials: engineering plastics, plastic doors and windows, sewer pipes, trunking drain pipes, electrical sockets, electrical appliance casings ect.

plastic recycling machine Application

HDPE/PP/PE/ABS/PVC hard plastic recycling line application: engineering plastics, plastic doors and windows, sewer pipes, trunking drain pipes, electrical sockets, electrical appliance casings ect.

PP/PE/LDPE plastic film recycling line application: plastic film,such as disposable plastic bags, agricultural films, packaging plastic film ect.

PET plastic bottle recycling washing line application:cold drink bottle such as mineral water bottle, soda water bottle, coke bottle ect.

EPS/EPE foamed plastic recycling line application:EPS/EPE foam such as buffer packaging, foam trays, foam lunch boxes, ect.

Clean plastic flakes

Final product: recycled plastic particles

Plastic Recycling Machine introduce

Efficient plastic recycling machine refers to a type of plastic recycling production line and plastic recycling machine used to process recycled waste plastics into clean plastic flakes or further processed into plastic granules.

Common plastic recycling lines include: PET washing line, PET plastic granule line, PP PE plastic recycling granule line, EPS EPE plastic recycling granule line.

Common machines used to recycle plastics include: plastic crusher, plastic shredder machine, plastic melting extruder, plastic pelletizer, water ring cutting pelletizer, plastic foam cold press, plastic baler, plastic bottle unpacking machine, plastic bottle friction washing machine, plastic bottle label removal machine, plastic washing pool, plastic cooling pool, plastic spin dryer, spiral feeder, vertical feeder, conveyor belt, feeder, screen, screening table, automatic knife sharpener.

The configuration requirements of the machines in the plastic recycling line will be different due to the different requirements for recycled waste plastics and recycling efficiency. If you want to start a plastic recycling project, you can leave me a message to let me know what plastics to recycle and what plastic recycling line or machine with what production capacity is needed. The sales manager can give you a perfect plastic recycling solution and quotation when contacting you.

Common important steps in plastic recycling lines

Plastic Sorting – Plastic Washing &Crushing – Plastic Dewatering – Plastic Melting and Extrusion – Plastic Strip Cooling – Plastic Strip Pelletizing-Plastic Granules Bagging.

Our service

Pre-sales service

Respond to your inquiry within 24 hours

If you are not sure about the recycled plastic material, the sales manager can help you analyze the recycled waste plastic material and provide suggestions.

Provide the best plastic recycling machine solution based on your raw materials, budget, machine capacity requirements, and site conditions.

In-sales service:

The sales manager supervises and follows up the manufacturing, installation, and delivery of the plastic recycling machine throughout the process, promptly communicates the progress of the plastic recycling machine to the customer, accompanies the customer to complete the equipment acceptance, and assists the customer in installing and debugging the machine.

After-sales service:

We provide online video installation teaching services. If necessary, the company can send technicians to the site to guide the installation of the equipment and train the operators. In addition, except for wearing parts, the machine is under warranty for one year.

Cooperation Case

Efficient Machine is exported to countries all over the world

Customers from Africa

Customers from the Middle East

Customers from Asia

Customers from Europe

machine certifications

plastic pelletizing lines feedback from Iranian customers

This video content is about the feedback from Iranian customers on the use of plastic pellet line. This plastic pellet machine produces 500kg plastic pellets per hour, and the customer’s plastic material is HDPE.

To learn more about waste plastic recycling machines and plastic pellet machines, please leave us a message for quick quotes and professional plastic recycling solutions.