Plastic Foam Cold Press Machine

plastic Foam Cold Press Machine For sale

Foam Cold Press Machine also called EPS EPE Cold Press Machine, It is a common machine in plastic foam recycling machine.

The main function of the Plastic Foam Cold Press Machine is to reduce the volume of plastic foam and reduce the space occupied by waste plastic foam during the recycling process, making it easier to store and transport.

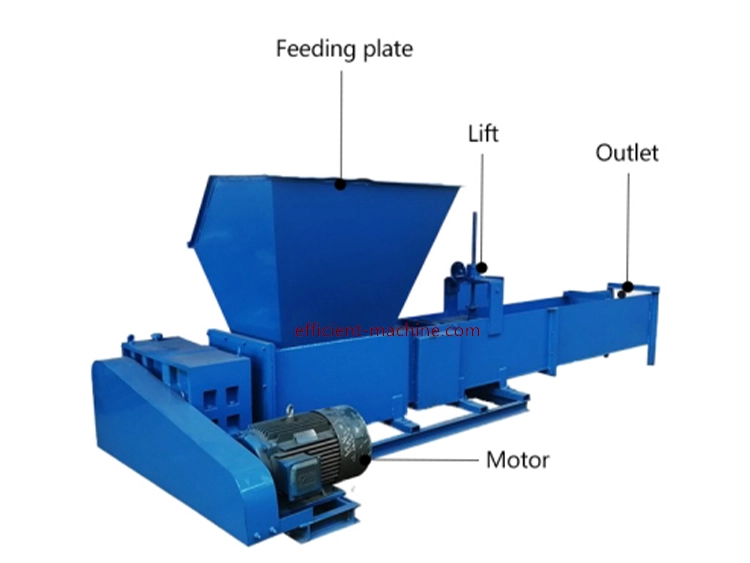

Plastic Foam Cold Press Machine Structure

Large size feed inlet: according to the different raw materials of the customer, tailor-made for the customer.

Pressure regulating device: there is a pressure regulating devicein front of the compression section to adjust the compression ratio.

Plastic Foam Cold Press Machine Features

Compacted EPS foam block up to 30 times.

High density after compaction.

After compaction, the foam block is easy to be cut off, storedand stacked.

Built-in pre-crushing mechanism, stable work efficiency.

Different sizes of feed opening sizes are available.

The equipment is simple and convenient, with strong adaptability and small footprint, suitable for compressing EPS in various occasions.

It is safe and easy to operate, with high efficiency, low noise and environmental protection.

It reduces the storage space and transportation cost of EPS and is widely used in factories, fishing ports, warehouses and supermarkets, etc.

Applicable Materials

Final Product

workshop

The plastic foam cold press machine produced by Efficient Machinery is a mechanical device that squeezes foam plastics and performs cold compression treatment based on the principle of spiral rotation to generate pressure.

When in use, the operator only needs to throw the foam into the hopper, and the foam is crushed and spirally compressed by the equipment’s tearing and crushing mechanism. After being processed by the spiral mechanism, square foam plastic compression blocks are produced. The foam volume is reduced exponentially, the density is increased, and it is conducive to storage and transportation during the foam recycling process.

How to choose a plastic foam cold press machine

1. It is recommended to purchase from a regular plastic foam cold press machine manufacturer. Some manufacturers produce equipment with unstable performance and high prices. Therefore, purchasing from a regular manufacturer can effectively guarantee the quality of the machine. Efficient Machinery has been engaged in the production of plastic foam recycling machinery for many years and can provide the most cost-effective foam cold press.

2. The model of the plastic foam cold press machine, because different consumers have different needs for equipment, manufacturers will produce a variety of models of foam block machine equipment. If we want to improve production efficiency, it is recommended that you choose a machine with a larger feed port under the same model, so that the efficiency of such equipment will be improved in future use. If you don’t know about many models, you can leave a message to tell us your needs. The sales manager will provide you with professional advice. We can also provide customized plastic foam cold press machine.

Successful cooperation cases

Precautions for using plastic foam cold press machine

In the process of using plastic foam cold press machine, it is inevitable that there will be failures. When failure occurs, the following points should be achieved:

1. The equipment reducer fasteners make loud noises. The solution is to tighten and replace the damaged fasteners.

2. The temperature of the plastic foam cold press oil tank rises. The solution is to add or subtract oil when the oil level of the plastic foam cold press machine oil tank is too high or too low. Hydraulic oil should be replaced in time. Check the bearings. If they are damaged, they need to be replaced.

3. The plastic foam cold press machine has oil leakage. This problem may be caused by poor sealing. Replace it with a new one or reseal it.

4. The plastic foam cold press machine cannot operate normally. First check whether the switch has poor contact. If so, repair or replace it. Check the motor coil to see if it is short-circuited. Low voltage may be caused by too long or too thin power cord.