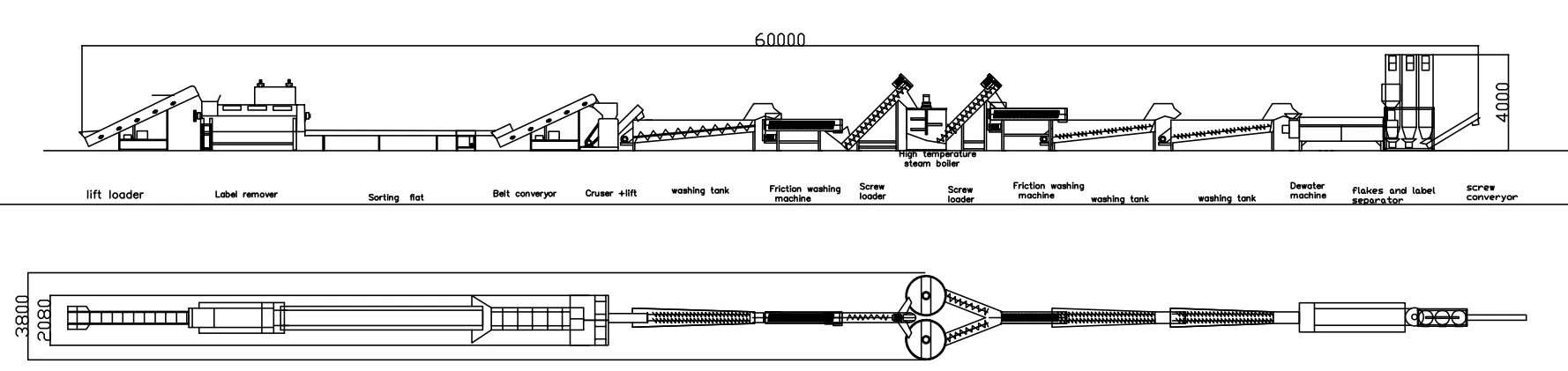

Plastic Bottle Recycling Machine

What Is Plastic Bottle Recycling Machine?

Plastic bottle recycling machine refers to a type of machine used to recycle waste plastic bottles and process them into clean plastic flakes or plastic particles.

The plastic bottle recycling line mainly includes a plastic bottle label removal machine, a plastic crushing system, a plastic washing system, and a plastic flake drying system.

According to the situation of the plastic recycling project, additional systems such as Bale Opener, Trommel, knife grinder, etc. can be added.

Our standard PET bottle washing lines are complete solutions for turning dirty PET bottle bales into clean PET flakes that can be used to produce polyester staple fibers or further processed into plastic pellets via pelletizing.

Our standard PET bottle recycling line is fully automatic, and customers can choose whether to replace some machines with workers to save costs according to the situation.

If you are a beginner, don’t worry, tell us your requirements, our professional design and development team and sales manager will provide you with a plastic bottle recycling solution that suits your project. Provide you with a unique and cost-effective plastic recycling machine.

Plastic Bottle Flakes Washing Recycling Process

Sorting plastic bottles

The sorting step is mainly to sort out impurities such as miscellaneous bottles, miscellaneous-colored bottles, and plastic films in waste plastic bottles. If the sorting step is not clean, then the cleaning process will not produce very good PET flakes.

Removing the label

This step is to remove the label from the plastic bottle. Since the trademark is generally different from the PET material, the trademark needs to be removed to obtain pure PET flakes. Removing the label on the PET bottle can be achieved by a manual or automatic de-labeling machine.

Crush plastic bottles

Use the plastic crusher to crush the whole plastic bottle into PET bottle flake. Since the plastic bottle caps are crushed together with the PET bottles, the crushed PET flakes contain plastic bottle cap fragments that are not PET materials.

PET bottle flakes washing

The cleaning process is the most important process in the PET bottle flakes washing line, so it needs to go through hot washing and rinsing and other cleaning processes. The pre-cleaning process is generally to remove the easily removable stains adhering to the surface of the bottle. Doing this process well can reduce the burden of the main washing process and reduce costs. The hot washing process is to add some chemicals to remove difficult-to-remove stains such as oil and glue during the hot washing process. The rinsing process has two functions, one is to rinse off the remaining floating objects, and the other is to rinse off the cleaning agent adhering to the bottle making machine.

Drying and storage

After cleaning, the PET bottle flakes need to be dried and stored to meet the needs of the subsequent melting process and made into finished products or plastic pellets.

PET flake quality

Color: The color of recycled PET flakes may vary depending on the source of the raw materials and the processing process. Common colors include transparent, blue, green, etc., and the specific color is determined by the customer’s raw materials.

No impurities: The recycled PET particles should contain as low a level of impurities as possible. Impurities may come from other plastics, grease, color, etc. that are not completely removed during the recycling process.

Moisture: PET is a moisture-sensitive plastic, so recycled PET flakes usually need to be dried, and the moisture content of PET flakes processed by our recycling line is less than 1%.

Application of PET flakes

- Processing into recycled plastic particles: Depending on the specific requirements of production, recycled PET flakes are usually made into different particle sizes. Common particle sizes are usually around 2-3 cm.

- Sold to plastic bottle flake buyers, melted and put into molds to produce new plastic bottles, accessories, toys, furniture, etc.

What machines does the plastic bottle recycling line include?

Debaler For PET Bottle Bales

Debaler For PET Bottle Bales Trommel

Trommel Conveyor

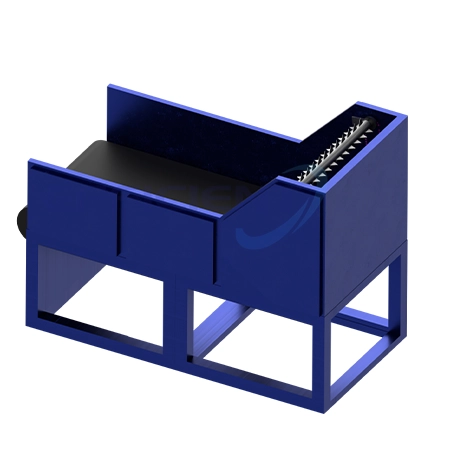

Conveyor PET Bottles Label Removing Machine

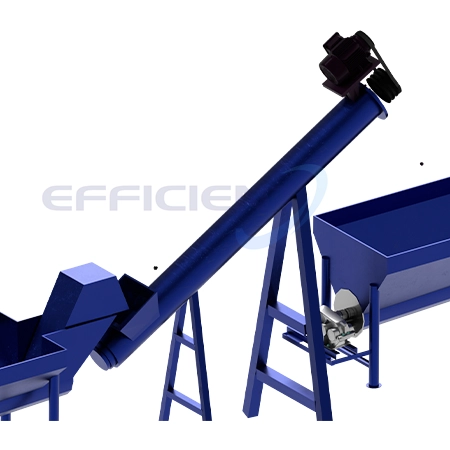

PET Bottles Label Removing Machine Plastic Crusher and Screw Conveyor

Plastic Crusher and Screw Conveyor Rinse Washing Tank

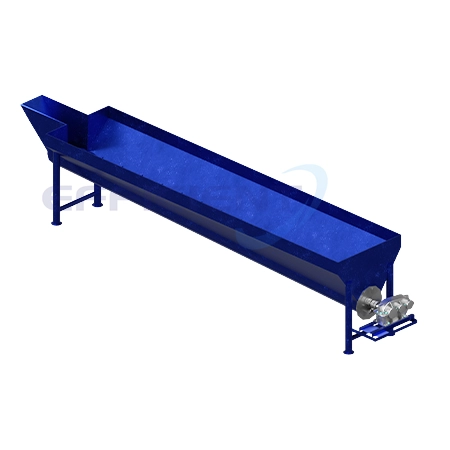

Rinse Washing Tank Spiral Feeding Machine

Spiral Feeding Machine High-Speed Friction Machine

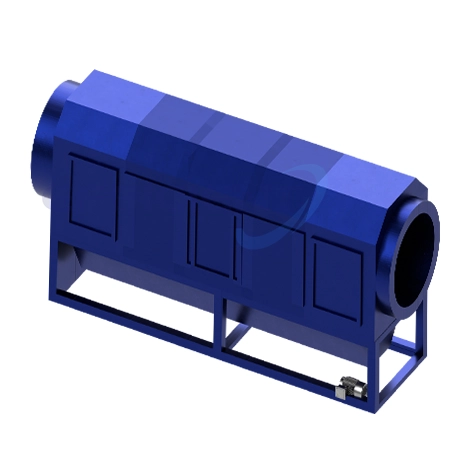

High-Speed Friction Machine Soak Hot Wash Pot

Soak Hot Wash Pot Horizontal Full-Grid Dryer

Horizontal Full-Grid Dryer Storage Silo

Storage Silo Control Cabinet

Control Cabinet