Introduction to Plastic Film Recycling Granulation Line

Plastic film recycling granulation line is a type of plastic recycling production line. Efficient Machinery standard plastic film recycling machine is suitable for recycling various plastic films: Common plastic film materials are:PP, PE, LDPE, disposable plastic bags, agricultural films, packaging plastic film ect.

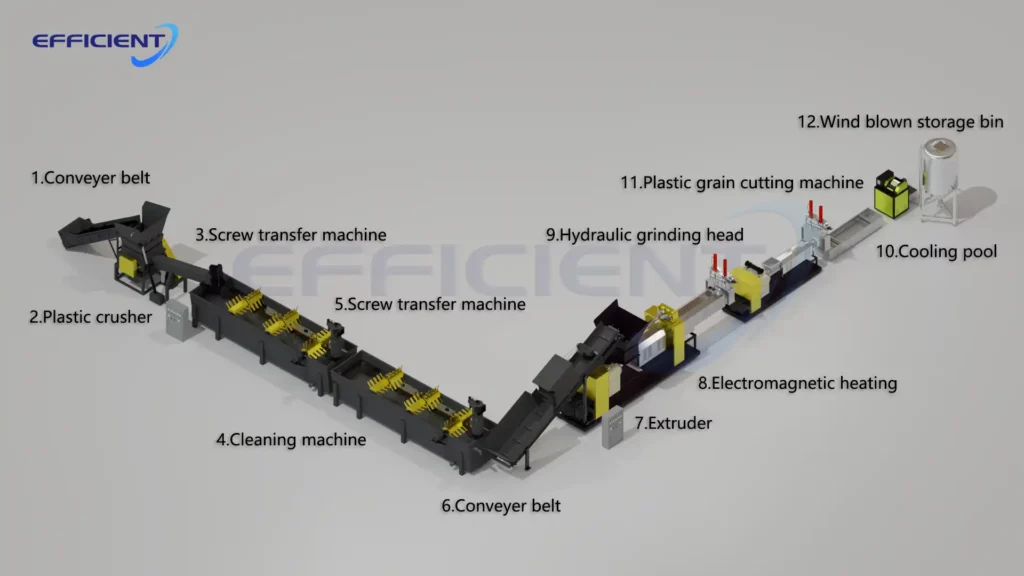

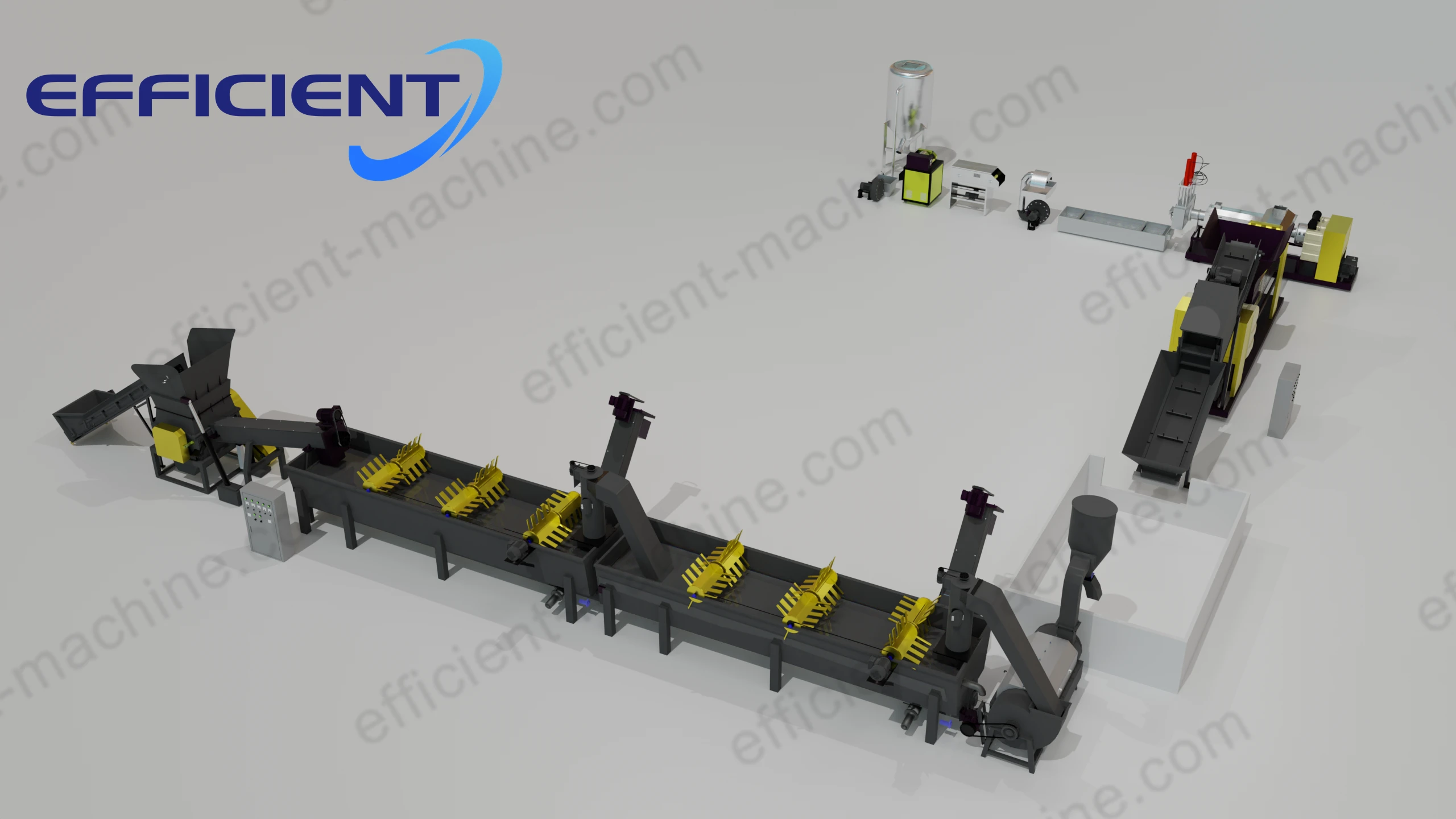

The production line mainly includes crushing, cleaning, drying, melting and extruding into strips, cooling, granulation and other processing processes, and finally produces high-quality plastic particles, which are then applied to the production of recycled plastic products.

Efficient Machinery Standard Plastic Film Recycling Machine Parameters

Capacity: 100kg-500kg/h, 1-5t/h.

Particle Length: 4mm(conventional), can be customized.

Particle Diameter: 3mm(conventional), can be customized.

Warranty: 1 year.

Raw Materials: plastic film,such as disposable plastic bags, agricultural films, packaging plastic film ect.

What materials can plastic film recycling machines process?

It is widely used in various conventional polyolefin soft plastics such as: plastic woven bags including cement bags, snakeskin bags, fertilizer bags, grain bags, industrial packaging bags, ton bags, space bags; and plastic film materials including agricultural films, ground films, greenhouse films, industrial packaging films; it can also be used for recycling and granulation of PE handbags, vest bags, and agricultural drip irrigation tapes.

Ton Bag

Ton Bag Agricultural Plastic Film

Agricultural Plastic Film Stretch Film

Stretch Film

Samples of recycled plastic particles produced by a plastic film recycling machine

The size of recycled plastic particles can be customized according to your requirements, and the color depends on the color of your raw materials and the chemical additives added. Generally, the raw materials are colorless and relatively clean, and the plastic particles produced are highly transparent.

What can the plastic Film recycling granulation line bring to users?

- Obtain considerable economic benefits. The manufactured plastic granules can be sold as recycled plastic raw materials, or processed into toys, furniture, parts and other plastic finished products for sale, thereby obtaining economic benefits.

- Improve efficiency. The plastic recycling granulation line processes waste plastic film into plastic granules, which greatly reduces the space required for storage and facilitates the storage, transportation and processing of recycled plastics. Thereby greatly improving production efficiency.

- Protect the environment. The recycling and reuse of waste plastic film reduces damage to the environment and contributes to the protection of the earth.

Processing of plastic film into plastic pellets

Plastic Sorting – Plastic Washing &Crushing – Plastic Dewatering – Plastic Melting and Extrusion – Plastic Strip Cooling – Plastic Strip Pelletizing-Plastic Granules Bagging.

plastic Film Recycling Machine Customization Service

All plastic recycling equipment is based on the actual situation of the customer’s materials. Our engineers with rich experience in manufacturing plastic recycling machines can provide customized solutions based on the actual production needs of the customer.

After we receive the inquiry, we will arrange professional sales staff to contact you as quickly as possible. According to your case, we will provide detailed suggestions and quotations. After payment, we will arrange production, pre-shipment commissioning, transportation, and provide installation technical support team services according to your needs.

If you are a plastic recycling business beginner don’t worry at all, the sales manager will give you a professional solution suitable for you. It is a one-stop service.

Cooperation Case

Efficient Machine is exported to countries all over the world

Customers from Africa

Customers from the Middle East

Customers from Asia

Customers from Europe

machine certifications

Our service

Pre-sales service

Respond to your inquiry within 24 hours

If you are not sure about the recycled plastic material, the sales manager can help you analyze the recycled waste plastic material and provide suggestions.

Provide the best plastic recycling machine solution based on your raw materials, budget, machine capacity requirements, and site conditions.

In-sales service:

The sales manager supervises and follows up the manufacturing, installation, and delivery of the plastic recycling machine throughout the process, promptly communicates the progress of the plastic recycling machine to the customer, accompanies the customer to complete the equipment acceptance, and assists the customer in installing and debugging the machine.

After-sales service:

We provide online video installation teaching services. If necessary, the company can send technicians to the site to guide the installation of the equipment and train the operators. In addition, except for wearing parts, the machine is under warranty for one year.