PET Recycling Machine Introduce

PET recycling machine is also called PET bottle flake hot water washing line,PET plastic washing line ect.

The PET waste plastic bottle recycling machine is designed for the processing of waste PET bottles such as mineral water bottles, Coke bottles, and pesi bottles. The PET bottle cleaning line includes delabeling, crushing, cleaning, drying, and packaging; processing waste PET bottles into PET bottle flakes is a complete automated waste plastic bottle recycling system.

Daily consumption of bottled beverages produces a large number of waste PET bottles, causing waste of PET bottle resources and environmental pollution. Our PET bottle washing and recycling machine can be used to recycle and reprocess a variety of PET bottles. Common ones include cold drink bottles such as mineral water bottles, soda water bottles, coke bottles ect.

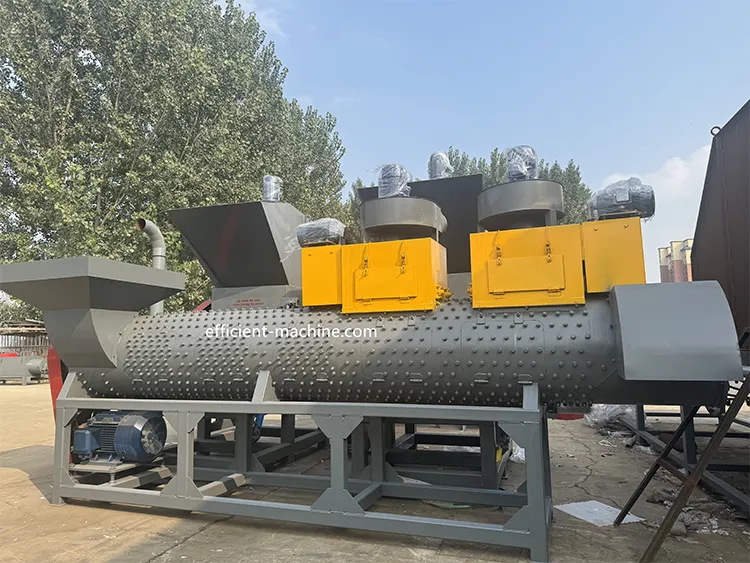

PET plastic hot cleaning line

PET plastic hot cleaning line

After being processed by our PET bottle washing and recycling machine, the final PET bottle flakes

PVC content/(mg/kg)≤500

True color content/% ≥90.00

Moisture/% ≥3.0

Impurity content/(mg/kg)≤800

Flake size:16mm-18mm, can be customized.

Dry and clean PET bottle flakes can be put into our PET plastic pelletizing machine to be directly made into plastic pellets. We can provide PET beverage bottle recycling machines with capacities of 500kg/h, 1t/h, 2t/h, 3t/h, 5t/h. The final product PET flakes has stable quality and various application levels.

The clean recycled PET bottle flakes processed by the PET bottle recycling machine can be used to produce polyester short fibers, PET tapes, pellets, PET transparent films and sheets, etc.

As a supplier of PET bottle washing and recycling machines, Efficient Machinery is committed to developing fully automated, intelligent, large-scale investment smart PET bottle recycling systems. Our plastic PET bottle recycling production line is used for PET bottle recycling, with functions such as PET bottle crushing, impurity cleaning, and bottle flake drying. Depending on the different standards of PET bottle production, the degree of contamination of the bottles, and the customer’s production requirements, we can provide a range of customized PET bottle recycling solutions.

PET Bottle Label Remove Machine

PET Bottle Label Remove Machine Plastic crusher

Plastic crusher Plastic washing tank

Plastic washing tank Deep Water Rinse Tank

Deep Water Rinse Tank

PET bottle recycling machine application

PET bottles, PET baling bricks, waste PET Coke bottles, soda bottles, drinking water bottles, juice bottles, tea beverage bottles and other mineral water bottles.

Plastic Bottle Recycling Process

dirty plastic bottle – plastic bottle after removing label – clean plastic bottle flake – recycled plastic particles.

Waste PET plastic granulator and washing machine

PET plastic granulator recycling production line is used for recycling waste PET, it is complete production line that produce PET pieces.

It mainly includes: sorting table–belt conveyor–label removing machine–belt conveyor–crusher–screw conveyor–washing tank–stuff-fetching machine–hot water washing tank–screw conveyor–frictional machine–washing tank–stuff-fetching machine–dehydrator machine–stock bin and packing.

Advantages Of Efficient Machinery PET Bottle Recycling Machines

Multiple capacities: fully automatic and intelligent PET bottle recycling system.

Safety Compliance: All our machines are manufactured as per CE standards. All rotating parts are equipped with safety fences or protective covers to prevent personal injury. A limit switch is installed at the inspection port. All lines are equipped with emergency switches.

Long life operation: All parts in contact with the material can be made of stainless steel SUS304, thickened steel plate, high strength and long life. All steel parts are anti-corrosion and pickled.

Water saving: Provide wastewater treatment, using less than 1 ton of water per ton of PET.

Energy saving: Reasonable factory structure design can not only clean materials, but also help customers save electricity consumption, thereby helping customers create more profits.

Our customers are all over the world

PET bottle recycling machine customization service

All PET bottle recycling equipment is based on the actual situation of the customer’s materials. Our engineers with rich experience in manufacturing PET bottle recycling machines can provide customized solutions based on the actual production needs of the customer.

Pre-sales service:

Respond to your inquiry within 24 hours.

If you are not sure about the recycled plastic material, the sales manager can help you analyze the recycled waste plastic material and provide suggestions.

Provide the best plastic recycling machine solution based on your raw materials, budget, machine capacity requirements, and site conditions.

In-sales service:

The sales manager supervises the manufacturing, installation, and delivery of the plastic recycling machine throughout the process, promptly communicates the progress of the plastic recycling machine to the customer, accompanies the customer to complete the equipment acceptance, and assists the customer in installing and debugging the machine.

After-sales service:

We provide online video installation teaching services. If necessary, the company can send technicians to the site to guide the installation of the equipment and train the operators. In addition, except for wearing parts, the machine is under warranty for one year.

machine certifications

What machines does the plastic bottle recycling line include?

Debaler For PET Bottle Bales

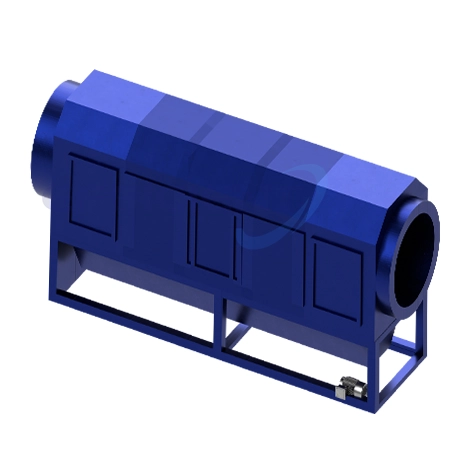

Debaler For PET Bottle Bales Trommel

Trommel Conveyor

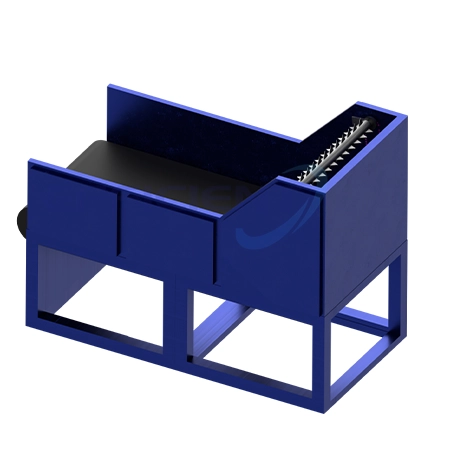

Conveyor PET Bottles Label Removing Machine

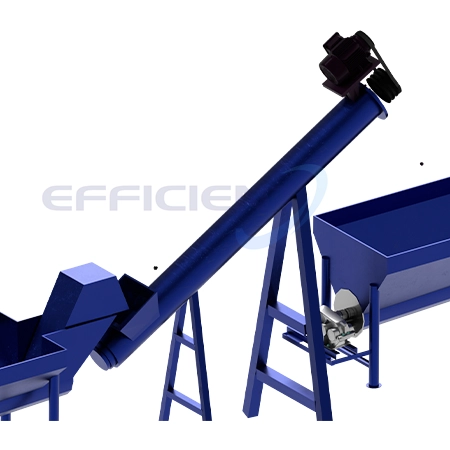

PET Bottles Label Removing Machine Plastic Crusher and Screw Conveyor

Plastic Crusher and Screw Conveyor Rinse Washing Tank

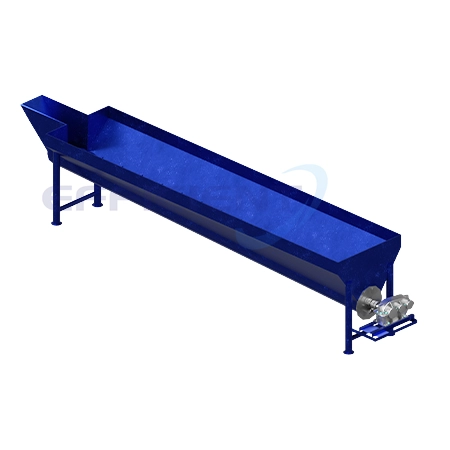

Rinse Washing Tank Spiral Feeding Machine

Spiral Feeding Machine High-Speed Friction Machine

High-Speed Friction Machine Soak Hot Wash Pot

Soak Hot Wash Pot Horizontal Full-Grid Dryer

Horizontal Full-Grid Dryer Storage Silo

Storage Silo Control Cabinet

Control Cabinet